Volatility across global markets caused by events such as the Covid-19 pandemic, international conflict, trade wars and supply chain issues has increased in recent years and created challenges for many industries. The wholesale distribution sector hasn’t escaped this. And with global events throughout 2025 likely to add further pressure, logistics providers need to foresee potential problems and start planning now to prevent any losses.

Here are five that the sector currently faces, and a few tips on how to turn them into opportunities:

1. Rising Costs

This is an unavoidable challenge for all industries, but wholesale distribution has been hit particularly hard. Not only have fuel costs increased globally but a shortage of drivers across the logistics sector mean labour costs are also increasing. In addition, the rise of online retail has made supply chains more international. Shipping across borders requires compliance with multiple countries’ regulations, resulting in higher costs. Plus, the introduction of protectionist tariffs by several countries (more of which are likely to come) mean the cost of doing business with customers overseas can be significantly higher.

Whilst these costs may be out of your hands, there are areas that logistics companies in the wholesale sector can have more control over. By using technology to improve planning and to optimize your delivery routes, you can make savings in other areas. For example, more efficient routes require less fuel and, in some cases, fewer vehicles, easing pressure on your resources.

2. Increased demand volatility

Consumers today have high expectations when it comes to getting what they want when they want it (clue, they want everything today!). However, as demand can fluctuate rapidly because of product trends, economic pressure and more, it’s hard to know exactly when retailers will need to have stock of specific products. This is an even greater challenge for retailers in fresh food or perishable goods, and for those who work on a just-in-time business model. For wholesalers, that means being able to respond quickly to customer demands and potentially change their operations with little notice.

This could be costly for logistics companies, as any last-minute changes can have a knock-on effect on resource management and route planning. That’s why building in flexibility from the beginning is crucial. Using AI-powered optimization technology can help you quickly plan and re-route deliveries with the least amount of disruption, and therefore cost, as possible.

Also Read: Improved delivery experience increases customer loyalty… and your bottom line

3. Disruption to Global Supply Chains

As mentioned in the introduction, one of the biggest challenges wholesale distribution faces is interruptions to supply. As trade has become more international, it’s created more choice for customers but simultaneously added complications to logistics. Companies no longer have to just manage local suppliers, but they now need to consider multiple partners in different countries for stock to reach their customers on time. This means that events happening in a completely different part of the world can have a major impact on your operations, which in turn can increase costs. Again, incorporating flexibility into your planning and execution by using the right technology can help you respond quickly to any delays and reduce their impact on your own finances and your customers’.

4. Greater Competition

Wholesalers have always been a key element of the retail supply chain, connecting large manufacturers of goods with consumer-facing sellers. However, as many industries are looking to cut costs, there has been a trend among manufacturers of cutting out the middleman and selling directly to their customers. As a result, delivery planning and execution has been brought in-house.

In addition, the manufacturing sector has seen consolidation in recent years which means there are more wholesalers competing for fewer opportunities. Of those competing, the ones who have integrated technology more effectively, such as Amazon, are seeing the greatest success.

To ensure your survival in the wholesale space, it’s vital to incorporate the latest logistics technology that can help increase efficiency at little-to-no extra cost. In doing this, you can add more value to the customer, not only by delivering exactly what they need well, but by freeing up time and resources to be able to focus on improving your overall customer experience.

DOWNLOAD WHITEPAPER

Optimize Your Deliveries with Advanced Route Planning

In today’s competitive wholesale landscape, efficient delivery is key to staying ahead. Our whitepaper explores how AI-driven route optimization can transform your logistics, helping you cut costs, improve reliability, and enhance customer satisfaction. Use our simple checklist to assess your current capabilities and discover how you can boost efficiency with minimal effort.

5. Providing end-to-end visibility

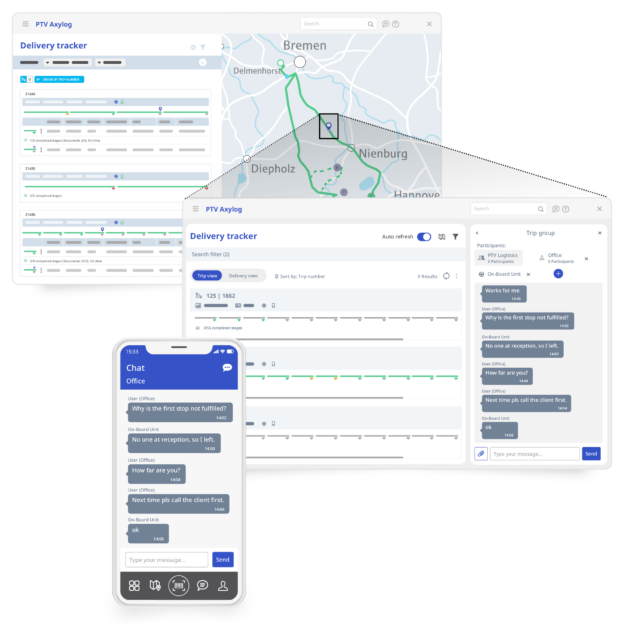

And one of the top priorities for customers is understanding where their goods are at any given time. With the expansion of supply chains due to the growth of international trade, and the increase in the number of stakeholders involved as inventory expands, tracking every delivery for every customer manually is time consuming and expensive. And managing delays on top of this adds an extra layer of complexity.

By incorporating real-time visibility technology all stakeholders can track the progress of their shipments. With this, they don’t need to wait to be informed of delays or changes to the delivery date and so can pre-empt potential disruptions and react more quickly to mitigate any impact on their business. It also provides peace of mind to customers around the security of their orders at very little extra cost compared to manual customer service outreach.

Related: Who should use real-time transport visibility platforms?

BONUS: Becoming sustainable

An additional challenge that the wholesale distribution sector faces is demand for more sustainable operations. Consumers want more things faster, but they also want this with minimal impact to the environment. This means retailers must demonstrate that they are working with responsible suppliers. The logistics industry is typically a heavy emitter of CO2, increasingly so as supply chains are more international. This makes it harder for companies in this space to deliver with less environmental impact.

Again, though, route optimization technology can help. Planning more efficient delivery routes not only reduces your costs but, by reducing the mileage for each trip, can also reduce CO2 emissions. And for those companies looking to switch to an electric fleet, optimization tools can also help you plan routes around charging stations, to ensure you’re getting the most out of the battery life.

Technology is the solution

The challenges faced by the wholesale distribution industry over the last few years are unlikely to disappear soon. In many cases, they will be exacerbated. However, the rapid advancement of logistics software means their impact will become less over time for those companies willing to integrate technology into their operations. This will not only result in better business outcomes for the companies, but it will strengthen the entire sector whilst also delivering for customers and the environment.