As of January 2025, 16 major Dutch cities including Amsterdam, The Hague, Utrecht, and Rotterdam have implemented zero-emission zones for commercial vehicles, with another 12 expected by 2028.

Clearly, logistics is undergoing a fundamental transformation. As cities adopt stricter emissions regulations and sustainability climbs higher on boardroom agendas, fleet managers are increasingly turning to electric vehicles (EVs) as a viable alternative to diesel.

But EVs bring a new set of planning constraints that render traditional route planning logic obsolete. To keep operations efficient and customer promises intact, it’s critical to understand how route planning must evolve when moving from diesel to electric.

To guide you through this shift, in this blog we will cover:

- Key differences: EV vs Traditional Fleet

- Advantages & challenges in EV fleet

- Hybrid fleets are becoming the reality

- How to plan efficiently for EV and diesel fleets

EV vs Traditional Fleet: What’s different?

At first glance, routing a diesel van or an EV might seem like a similar task: get goods from A to B as efficiently as possible. But the operational realities are starkly different:

| Aspect | Traditional fleet (Diesel) | Electric fleet (EV) |

|---|---|---|

| Refueling Time | Approximately 5–10 minutes at fuel stations. | Charging times range from 30 minutes (DC fast charging) to several hours (Level 2 charging), depending on charger type. Charging at company depots is typically much cheaper and more predictable—public charging can cost up to three times more and often varies significantly, leading many fleet operators to avoid relying on public networks.

|

| Fueling Infrastructure | Extensive network of fuel stations available nationwide. | Charging infrastructure is still developing, with availability varying across regions. For trucks, the challenge is even greater—dedicated truck charging stations are still rare and must meet specific requirements like high-speed charging, sufficient space and height, and access for trucks with trailers.

|

| Route Planning Complexity | Standard route planning based on distance and time. | Route planning for EVs must account for battery range, charging station locations, and charging times—adding significant complexity. It also involves charging resource planning, considering different types of charging: depot charging, overnight charging, destination charging, or public charging—all of which vary in availability, speed, and cost.

|

| Energy Efficiency | Diesel engines are less efficient, with energy losses in combustion and transmission. | Electric drivetrains are significantly more efficient, converting over 77% of electrical energy from the grid into movement. In contrast, internal combustion engines typically convert only about 12–30% of fuel energy into motion. Additionally, regenerative braking systems can recover up to 14% of energy normally lost during braking, further boosting overall efficiency.

|

| Emissions | High CO₂ and particulate emissions contribute to air pollution and climate change. | Zero tailpipe emissions contribute to improved air quality and reduced greenhouse gas emissions. However, it’s important to consider CO₂ equivalents in the overall energy efficiency comparison, especially Scope 2 emissions. The carbon footprint of electric vehicles varies significantly depending on the energy mix used for electricity generation. Using renewable energy sources for charging can greatly reduce emissions and mitigate country-to-country differences.

|

| Maintenance Requirements | Regular maintenance needed for engines, exhaust systems, and fuel components. | Lower maintenance needs due to fewer moving parts; however, battery health monitoring is essential.

|

| Operational Costs | Fuel costs fluctuate with oil prices; maintenance costs can be high over time. | Lower operational costs due to cheaper electricity and reduced maintenance needs, though battery replacement can be costly—especially when charging at the depot. Charging in public networks can be significantly more expensive and less predictable, which can impact overall operational costs.

|

| Regulatory Compliance | Subject to stringent emissions regulations, especially in urban areas, including the emergence of Zero Emission Zones (ZEZ) in several countries that restrict or ban high-emission commercial vehicles. | Often eligible for incentives and exemptions in low-emission zones; however, battery disposal regulations are evolving.

|

While these differences shape how fleets operate today, they also set the stage for both exciting opportunities and complex challenges that come with adopting electric vehicles.

Understanding the opportunities and challenges of EV Fleets

Often, the industry assumes switching to electric vehicles (EVs) is a simple swap, but it requires a whole new approach to route planning and fleet management.

The transition to electric trucks offers tremendous potential for reducing emissions and cutting operational costs. However, this shift also comes with a unique set of challenges that logistics companies must navigate to unlock its full benefits.

Challenges

One of the biggest hurdles is the high upfront capital cost—both for electric trucks and the necessary charging infrastructure. Unlike diesel fleets, electric vehicle (EV) operations demand high vehicle utilization and optimized routing to be economically viable. Without these operational efficiencies, EVs risk being more expensive to run.

Additionally, electricity pricing varies significantly across markets, directly impacting the cost competitiveness of EVs. Driver behavior also plays a crucial role—practices like eco-driving and strategic charging schedules are no longer optional but essential to avoid battery range limitations.

Finally, the evolving regulatory environment, including carbon pricing mechanisms like the European Emissions Trading System (ETS II), adds complexity but also opportunity.

Opportunities

Rising carbon prices—projected to reach up to €149 per ton by 2030—are a powerful accelerator of EV adoption, with every €50 increase improving EV economics by approximately 2-3% compared to diesel.

Operational optimizations, such as drop trailers, smart routing, and overnight charging, can reduce costs by up to 10% below diesel prices by 2030. Real-world collaborations, like the partnership between Nestlé and SENNDER in Germany, demonstrate that integrating EVs into dedicated transport flows with reliable charging and green electricity procurement is both feasible and cost-effective today.

Early adopters who proactively invest in infrastructure, operational planning, and energy strategies will not only reduce emissions but gain a significant competitive advantage as the market accelerates.

The rise of hybrid fleets

The reality is most carriers won’t switch to 100% electric overnight. Diesel fleets aren’t disappearing anytime soon, but EV adoption is accelerating, meaning planners must manage both. This mix introduces unique challenges: routing rules for diesel don’t always apply to EVs, which have different range limits, charging requirements, and depot availabilities. Adding sustainability KPIs further increases operational complexity.

When managing electric fleets, it’s critical to use solutions designed for their specific needs such as real-time battery range monitoring, smart charging point integration, and dynamic route adjustments that maximize efficiency and minimize downtime. These capabilities not only enhance planning accuracy but also ensure that fleets meet delivery commitments sustainably and cost-effectively.

Read about the award-winning tool that is leading the way in EV fleet efficiency here.

At the same time, some companies prefer to enhance their existing systems rather than switch platforms entirely. For them, PTV Developer’s Routing API offers flexible integration of precise EV routing features addressing challenges like range estimation, charging station availability, and heterogeneous fleet management, allowing logistics teams to maintain control while accelerating their transition to electric vehicles.

How to optimize routes for EV and diesel fleets

Managing a mixed fleet of electric and diesel vehicles means balancing very different operational needs. Each type has unique range limits, refueling or charging requirements, load capacities, and route preferences. So how can fleet managers keep operations efficient and reliable?

It starts with intelligent route planning that goes beyond simple point-to-point navigation.

Here are some of the key strategies for optimizing routes both EV and diesel fleets:

- Segment fleet deployment strategically: Assign electric vehicles (EVs) to routes with shorter distances, frequent stops, and accessible charging infrastructure—often urban or regional deliveries. Diesel vehicles, with their longer range and faster refueling, remain ideal for long-distance hauls or areas where charging options are limited.

- Incorporate dynamic data: Leverage live traffic updates, toll variations (including emerging CO₂-based tolling), and road restrictions to optimize costs and delivery times for both EV and diesel vehicles.

- Plan around refueling and charging: Unlike diesel refueling, which is generally quick and widely available, EV charging can take longer and varies by station type and availability. Effective planning must consider charger locations, wait times, and charging speeds to avoid operational delays.

- Optimize energy and fuel efficiency: Route algorithms should factor in elevation changes, stop-and-go traffic, and average speeds to minimize energy consumption for EVs and fuel use for diesel trucks, extending vehicle range and reducing costs.

- Use centralized, unified planning tools: Avoid separate systems for different vehicle types. An integrated platform that manages the entire fleet holistically enables better dispatch decisions, resource allocation, and cost control.

EV fleet specific tips:

- Maximize use of electric vehicles within their available range. Plan routes so EVs cover as much distance as possible without needing mid-route charging, making the most of their battery capacity.

- Prioritize depot charging whenever possible. Charging at your own facility is usually cheaper, faster, and more reliable than relying on public chargers.

- Extend vehicle usage hours smartly. Consider using multiple drivers or shifts to keep EVs on the road longer, balancing driving and charging times efficiently.

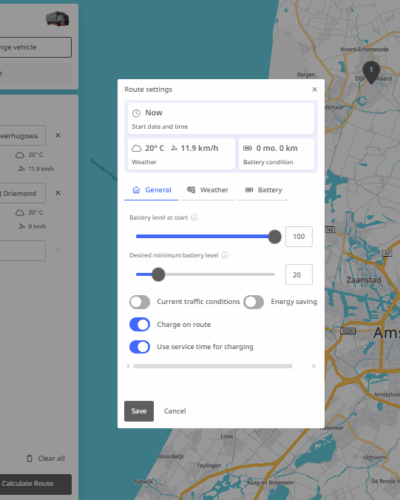

- Simulate different charging and routing scenarios. Use route planning tools to test various options, including charging schedules, to find the most effective way to keep your EVs moving.

- Optimize route choices based on regional conditions. For example, in countries like Germany, Austria, and Switzerland, plan routes that allow electric trucks to avoid toll roads, reducing costs.

For fleets in transition, planning grows complex but critical. McKinsey predicts electric fleets will have 15–25% lower total cost of ownership by 2030 due to battery cost drops, better utilization, and stable electricity prices.

EVs and diesel require distinct planning logic—from vehicle profiles to infrastructure and timing—so one-size-fits-all doesn’t work.

That’s why many rely on advanced route optimization tools like PTV Logistics’ software, which intelligently manage mixed fleets by analyzing vehicle type, range, fueling needs, pace, and constraints in real time—ensuring smarter, more efficient operations, whether diesel or electric powered.