The last mile – the final step in getting a product from a warehouse or distribution center to the customer’s doorstep – is the most expensive. In some cases, making up more than 50% of total delivery operations costs. And many of these costs are hidden, which means they can easily spiral out of control if not kept in check.

But there is a way to solve many of the expensive challenges in one go, enabling you to reduce costs across different fronts. And that’s by using route optimization software for last mile operations, because this technology is designed to increase efficiency in route planning by considering various factors like traffic, delivery times and vehicle capacity, helping you achieve meaningful cost savings.

LAST MILE DELIVERY INSIDER

Before You Lose More Money on Last‑Mile Delivery…

Last‑mile costs are rising faster than ever and most of the damage happens silently. Hidden inefficiencies, empty miles, missed deliveries, and unpredictable disruptions drain budgets long before anyone notices. Our whitepaper uncovers the real reasons behind soaring last‑mile expenses and reveals where logistics teams are recovering up to 20% in savings through smarter planning, real‑time visibility, and dynamic optimization.

1. Design more efficient routes

A route optimization tool will always beat a human planner when it comes to efficient route design, particularly for multi-stop routes. That’s because this software can leverage big data – historic and real-time – and algorithms to quickly calculate the best route based on your business objectives. As a result, it can reduce the number of kilometers driven for each delivery route (saving you fuel) and maximize the productivity of each driver. With fewer drivers needed to do the same amount of work, it also frees up capacity to allow for more drop offs overall. Not only do you save money, but you also have the potential to increase revenue.

2. Improve resource management

Using route optimization software can help you manage your resources more effectively. By optimizing delivery schedules and grouping the drop offs more effectively, e.g. by proximity to each other or by size of truck required, you can reduce the number of vehicles and drivers needed.

3. Lower maintenance costs

By reducing the number of kilometers each vehicle needs to drive for each delivery, you reduce the amount of wear and tear each one experiences over time, lowering overall maintenance costs. And, by reducing the number of trucks needed to fulfil your deliveries, you can alleviate pressure on each vehicle by swapping them in and out more regularly. This helps you extend the life of your fleet, reducing the frequency which you need to replace your vehicles.

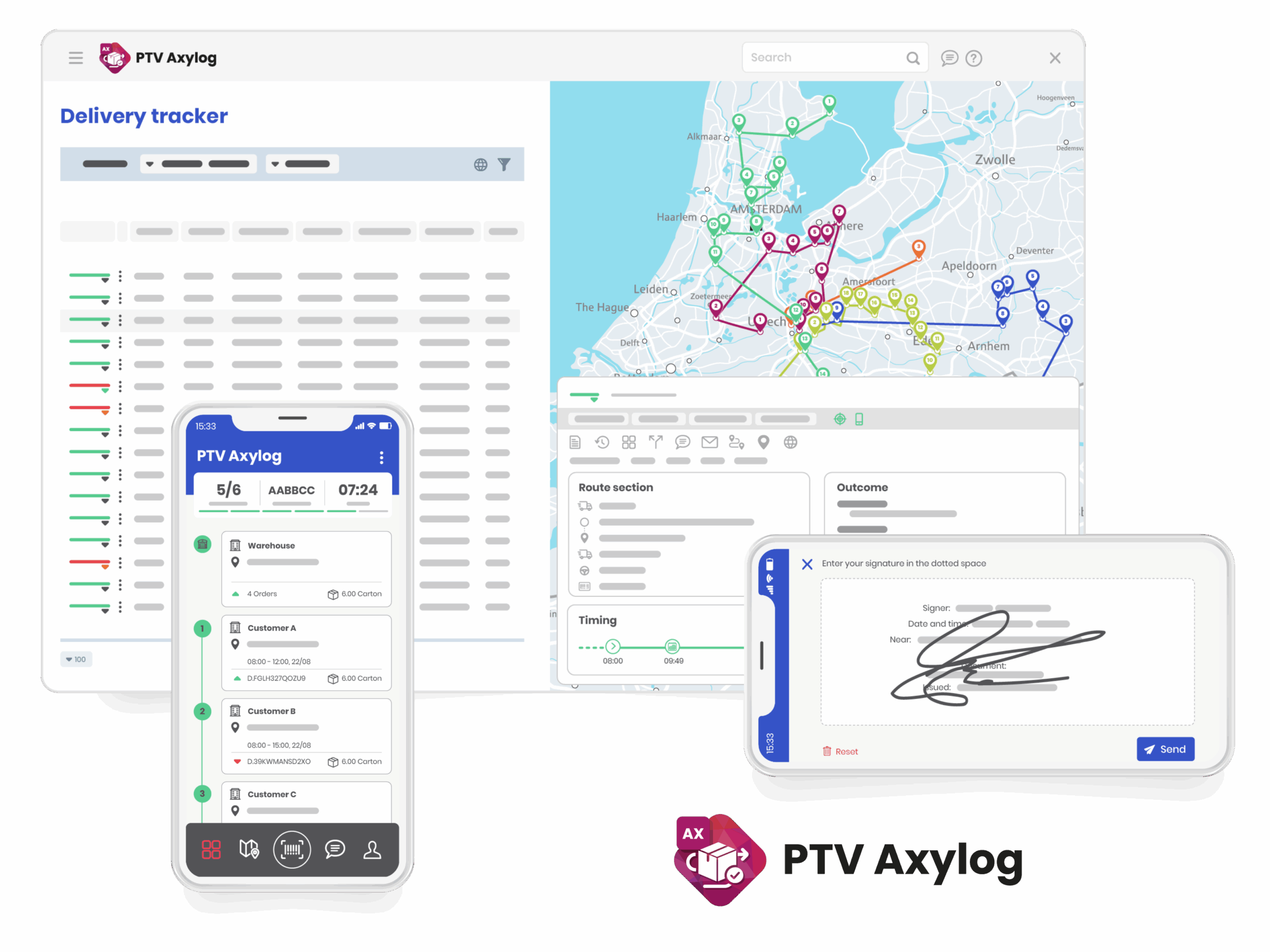

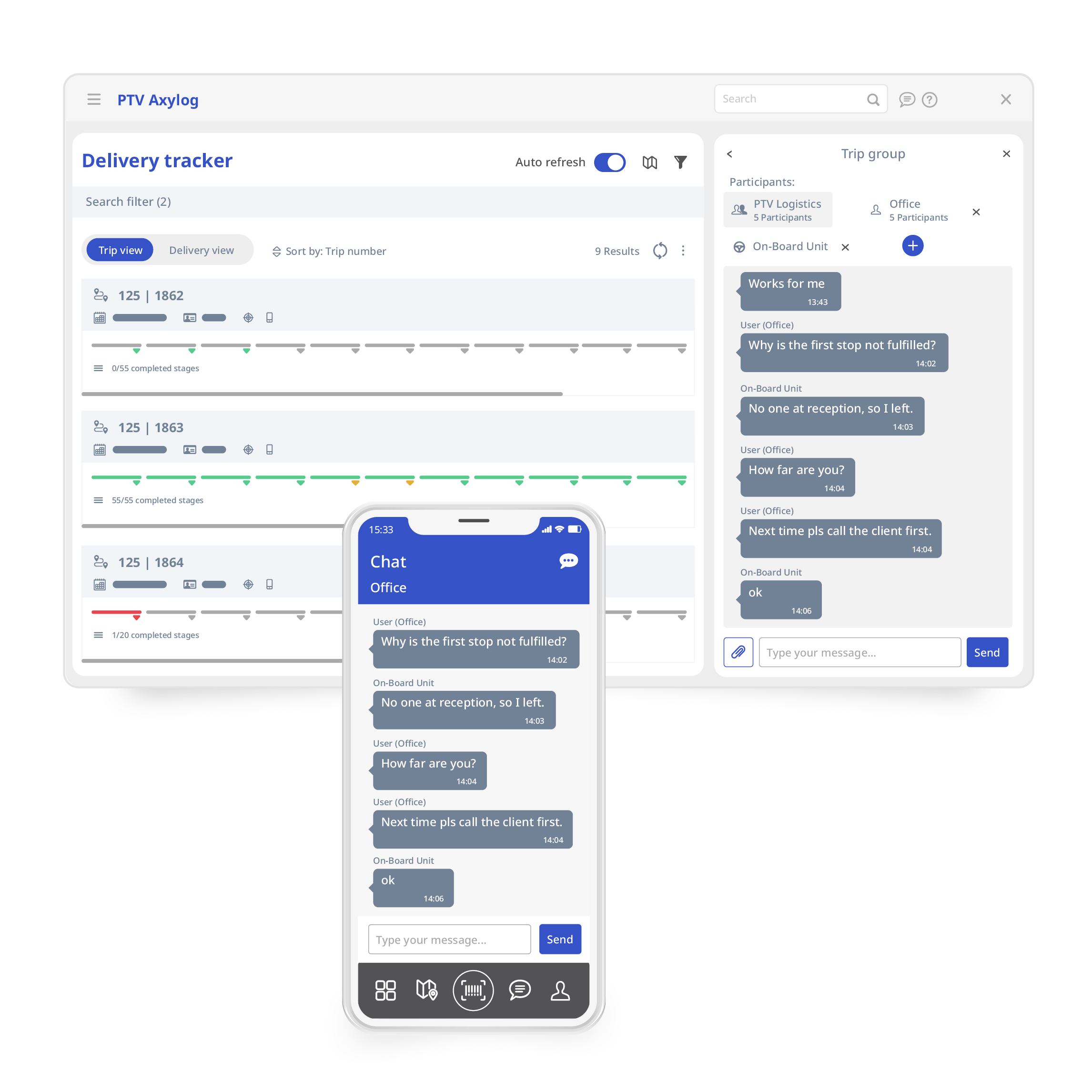

4. Manage costly last-minute changes

Even the best made plans can go awry. There are multiple factors that can disrupt a delivery, from heavy traffic to a missed delivery. And disruptions are expensive. However, with route optimization software you can take real-time data gathered by your transport management tool and replan to find the quickest route based on the current situation. This reduces delays and keeps the delivery costs low.

5. Reduce empty miles driven

One of the quickest ways to lower last mile costs is to reduce empty miles – the number of kilometers a truck drives without any load. Empty miles are expensive as they entail costs (fuel, labor, maintenance) without bringing revenue. These can be reduced by planning routes more efficiently – ensuring the last drop off is close to the depot – or by incorporating customer returns into deliveries. In both cases, route optimization software can help you find the most efficient way to reduce empty miles.

6. Tackle demand fluctuation better

Retail demand is often seasonal and affected by consumer trends. These fluctuations can be hard to predict and expensive to manage as it requires logistics companies to respond quickly, scaling their operations up and down to meet demand. Route optimization software for last mile can help by quickly factoring changing volumes into route design to ensure they remain efficient and cost-effective.

7. Minimize missed deliveries

Another big last mile cost is missed deliveries. If a parcel cannot be delivered because no one’s at home, the delivery will need to be rescheduled. This results in additional planning costs and more kilometers to redeliver. However, route optimization can be used to minimize missed deliveries in the first place. By offering customers specific delivery windows, they can choose a time they know they’ll be home. This adds another constraint when designing delivery routes, adding more complexity to the problem, but route optimization software can handle this easily. And, if a missed delivery does need to be rescheduled, a route optimization tool can be used to find the most cost-effective way to do it.

8. Increase driver satisfaction

As the logistics industry globally faces a driver shortage, it’s expensive to have to rehire too often. To keep recruitment costs down, logistics companies should focus on enhancing driver satisfaction. Route optimization software can help with this by factoring driver preferences into route design. By using technology to do this, rather than manual planning, you can still ensure the most efficient routes, even with additional driver constraints.

9. Automate admin tasks

Labor is another key cost in last mile delivery. Route planning and managing paperwork are time-consuming tasks that don’t offer a particularly high ROI, so it makes sense to automate these processes where possible. Route optimization software that leverages AI can analyze delivery data and automate route planning, reducing the workload of planners, and free-up time for them to focus on strategic tasks that add more value to the business.

Want to choose the right delivery technology? If you’re exploring tools that automate and streamline last mile operations, you’ll find this blog helpful:

What to Look for in a Last Mile Delivery App

Route optimization software reduces costs by increasing efficiency

Ultimately, the most effective way to reduce your last mile costs is to increase efficiency in your operations. To achieve the greatest amount of savings and generate a positive ROI, you need to invest in route optimization software. By leveraging advanced algorithms, it can quickly analyze your delivery data and design the most efficient routes to maximize cost savings, factoring in multiple constraints including vehicle availability, driver demands and narrow delivery windows.

Investment in this sort of technology not only increases the savings you can make but also opens new revenue opportunities by increasing the capacity for additional deliveries without having to grow your vehicle fleet or driver pool. And by automating planning, it frees up logistics managers and planners to focus on strategic projects that add more value to the business.

If you’re interested in learning more about how route optimization software can reduce costs in your last mile operations, contact us for a free demo.