“The transition to clean energy is happening worldwide and it’s unstoppable. It’s not a question of ‘if’, it’s just a matter of ‘how soon’ – and the sooner the better for all of us.”

— Dr. Fatih Birol, Executive Director of the International Energy Agency (IEA)

It’s a clear signal: the logistics sector is standing at a pivotal moment. Electrification is no longer optional or futuristic. It’s an active, accelerating movement. With policies shifting, technology advancing, and pressure mounting to decarbonize operations, the question for logistics teams isn’t whether to act, but how to do it efficiently.

This blog is for logistics professionals who want clarity on the same. Whether you’re exploring EVs for the first time or scaling an existing electric fleet, we’ll walk through the essential stages: from assessing readiness to optimizing routes using practical insights from real-world tools and scenarios.

Key Steps to Electrify Your Fleet

Electrifying your fleet is a strategic move that requires careful planning across operations, infrastructure, and cost. This guide outlines the essential steps logistics teams should follow to transition smoothly to electric vehicles (EVs).

Based on industry best practices, here’s a structured approach to electrifying your fleet:

Stage 1: Assess and Strategize

Before investing in EVs, clarify your why. Are you motivated by cost savings, regulatory compliance, or customer expectations? Your goals will shape the pace and scope of your transition.

Key considerations at this stage:

- Fleet readiness: Match vehicle types, routes, and payloads with EV capabilities. Short-haul urban deliveries may be ideal starting points.

- Charging capacity: Evaluate whether your depots and energy supply can handle the added demand. If not, explore options for upgrades or renewable integration.

- Growth planning: Factor in future fleet expansion when assessing vehicles and charging solutions.

- Transition strategy: Decide between gradual replacement (one-for-one as vehicles retire) or full fleet conversion. Each has cost and operational trade-offs.

- Vehicle selection and financing: Shortlist EVs that fit your needs and compare buying versus leasing models to manage upfront costs.

A solid strategy here prevents costly missteps later.

Stage 2: Simulate and Plan

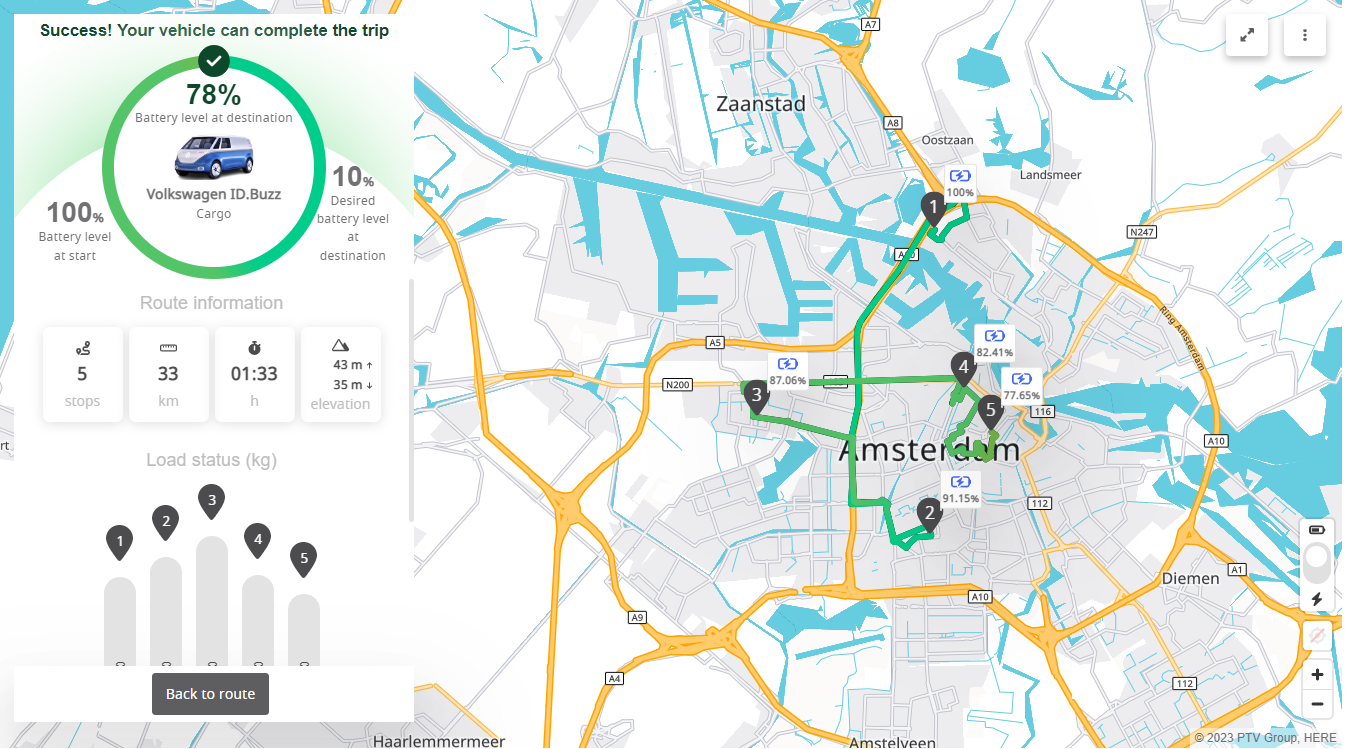

Once your strategy is in place, the next step is to test before you invest. Simulation tools let you model how different EVs would perform in your specific operations, considering factors like:

- Route profiles (urban vs. long-haul)

- Weather conditions

- Payload variations

- Toll costs and regional regulations

This digital “trial run” helps you understand range limitations, charging needs, and overall feasibility. It also informs decisions about:

- Charging infrastructure: Number, type, and location of chargers (including potential en-route charging).

- TCO modeling: Compare diesel vs. electric costs over vehicle lifetimes, including fuel, energy, and maintenance.

- Optimization opportunities: Once EVs make up 10% or more of your fleet, smart routing can unlock significant cost and CO₂ savings.

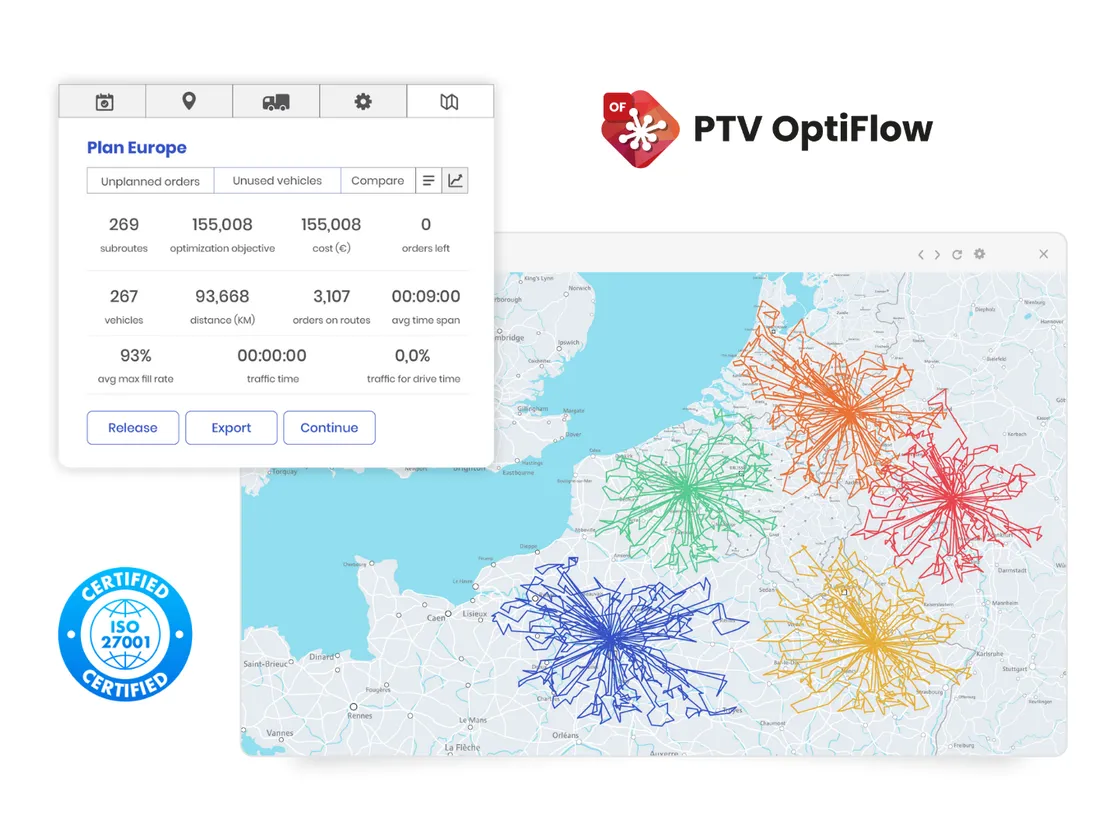

Tools like PTV OptiFlow allow logistics planners to simulate delivery schedules based on energy use, charging availability, and mixed fleet operations.

Stage 3: Operate and Scale

After piloting your first EVs, it’s time to gather real-world insights and refine.

- Pilot deployments: Run controlled test routes to spot practical issues such as driver behavior or unforeseen charging delays that simulations can’t fully capture.

- Real-time monitoring: Use telematics and transport management platforms to collect performance data, then feed it back into planning.

- Route automation: Adopt predictive and automated route optimization to preserve battery life, lower costs, and scale EV operations more smoothly.

- Smart charging: Implement load balancing and time-of-use charging to cut costs and extend battery lifespan.

- EV navigation: Equip drivers with specialist software that identifies suitable charging stations along the way.

By continuously refining operations, your fleet transition evolves from small pilots into scalable, cost-efficient electrification.

Taking the First Step Toward a Fully Electric Fleet

The shift to EVs is inevitable and the conditions to support it are already here. Governments are tightening emissions regulations, customers expect sustainable deliveries, and EV technology is advancing rapidly.

Being an early mover brings advantages: lower total cost of ownership, reduced operating costs, and a stronger competitive edge. But electrification isn’t one-size-fits-all. The right path depends on your business goals, operational realities, and financial outlook.

At PTV Logistics, we provide the simulation, routing, and optimization tools that make fleet electrification practical, scalable, and cost-effective.