Electric trucks are no longer a niche experiment. They are fast becoming central to Europe’s logistics transformation, powered by fleet electrification solutions that help businesses adapt to new emission standards. As CO₂ regulations tighten, charging infrastructure scales (but not without growing pains), and energy costs fluctuate, logistics companies face high stakes.

In this interview, we sit down with Michael Hubschneider, Senior Product Manager at PTV Logistics, to unpack how the PTV EV Truck Route Planner is evolving to simplify route planning for electric fleets. We explore the pressing challenges logistics companies are navigating today and the emerging technologies shaping the future of fleet electrification.

1. What’s the biggest blind spot logistics teams have when planning routes for electric trucks?

“The biggest blind spot is treating electric trucks like diesel trucks with a battery – focusing purely on range and charging without understanding how this fundamentally changes the entire logistics operation.

- The Data Gap Problem: Without digital twins that model real truck performance in their specific logistics scenarios, companies fall back on rough thumb estimates or expensive trial-and-error with actual vehicles. Simulating range consequences under real operational conditions – payload variations, terrain, weather, multi-stop routes – before committing to purchases is essential but rarely done.

- The Missed Optimization Opportunity: The second critical blind spot is assuming electric trucks must replicate existing diesel operations. This leads to conservative “electrification quotas” that miss the real TCO advantage.

EVs have significantly lower operational costs – the key is maximizing their utilization over longer daily operating windows, even if that requires intermediate charging. A diesel truck might run 8 hours and park.

An EV could potentially run 12+ hours with a mid-day charge, dramatically improving asset utilization and lowering cost per delivery.

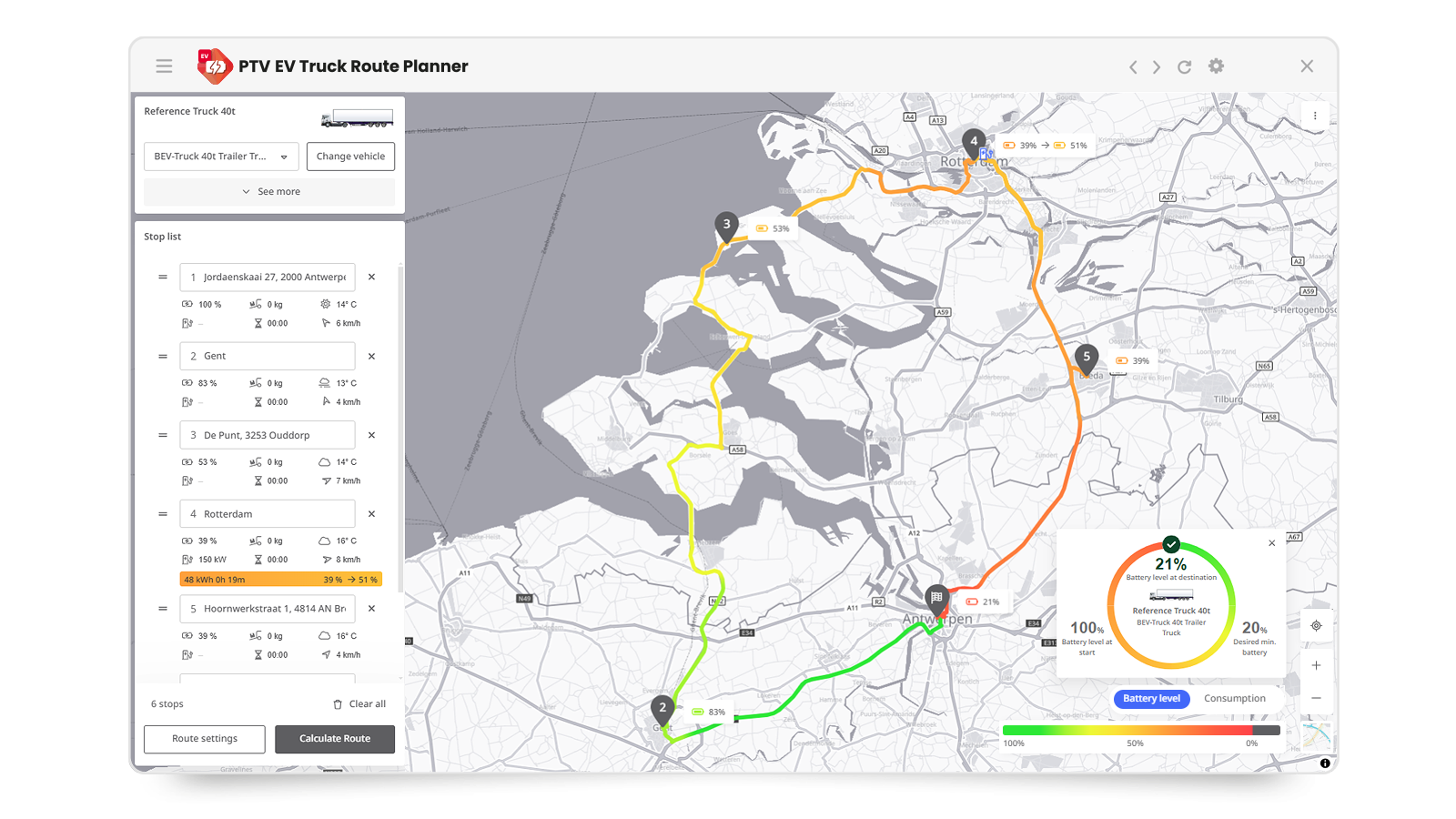

This also unlocks intelligent mixed-fleet optimization: assigning vehicles based on route characteristics, costs, and range capabilities. Put EVs on routes where their economics shine (predictable urban routes with charging access), keep diesel for the edge cases. But you can only do this if you can actually model and compare the scenarios.

The teams winning at fleet electrification aren’t just buying electric trucks – they’re redesigning their operations based on what EVs do better than diesel, using simulation to find the optimal deployment strategy before spending millions.”

Dive deeper – Diesel fleet vs EV route planning: What’s different and why it matters

2. Why did PTV Logistics decide to develop the PTV EV Truck Route Planner? What recent trends or industry shifts have made such a tool indispensable for fleet operators?

“Since 2023, the adoption of electric trucks has accelerated across Europe, driven by stricter CO₂ fleet regulations, zero-emission targets, and rising energy costs. Fleet operators need tools that optimize both operational efficiency and Total Cost of Ownership (TCO). The PTV EV Truck Route Planner helps them navigate these shifts, supporting large-scale electrification and day-to-day route planning challenges.”

3. How does the tool help companies estimate and optimize Total Cost of Ownership (TCO), including factors like battery degradation, energy pricing, charger infrastructure, and route-based energy consumption?

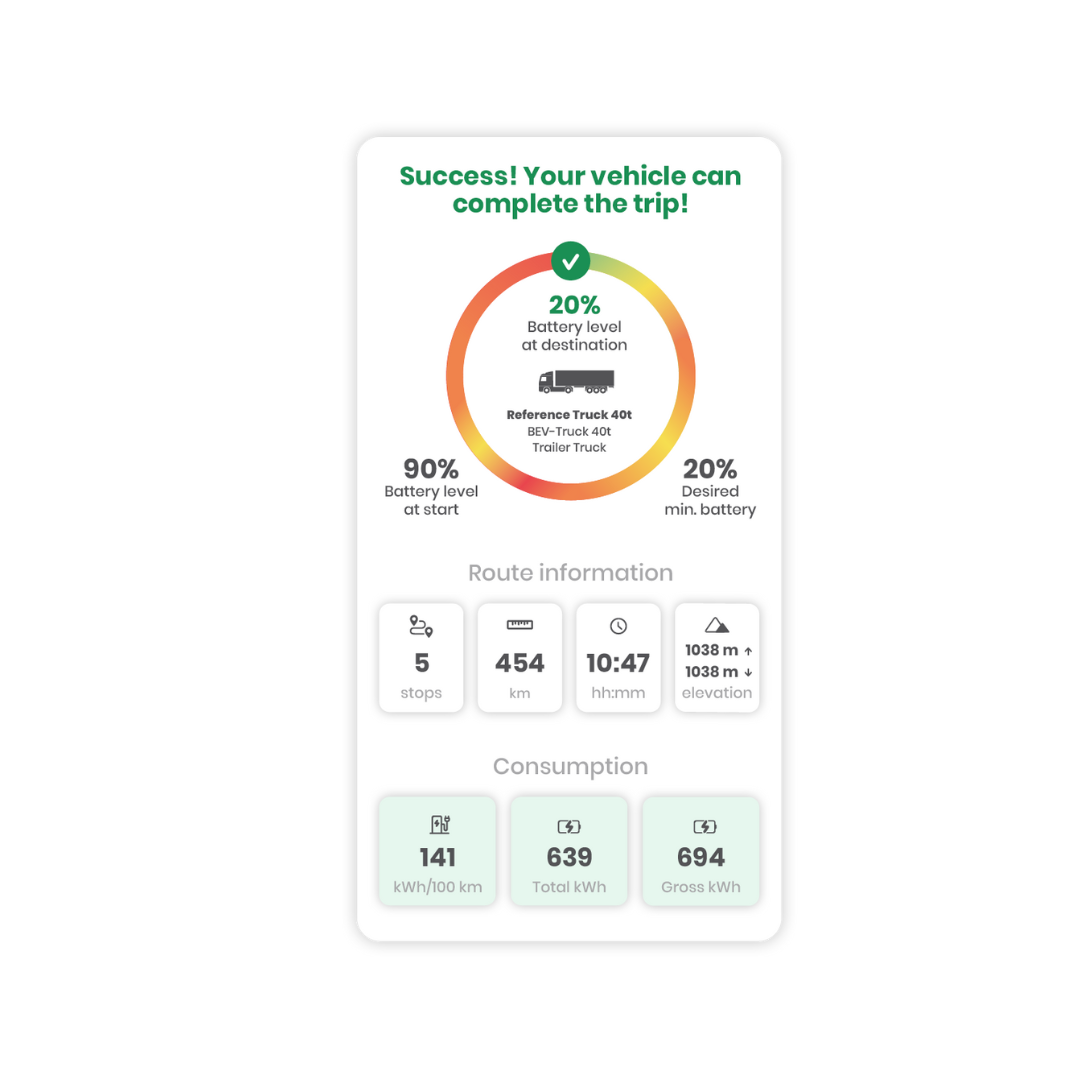

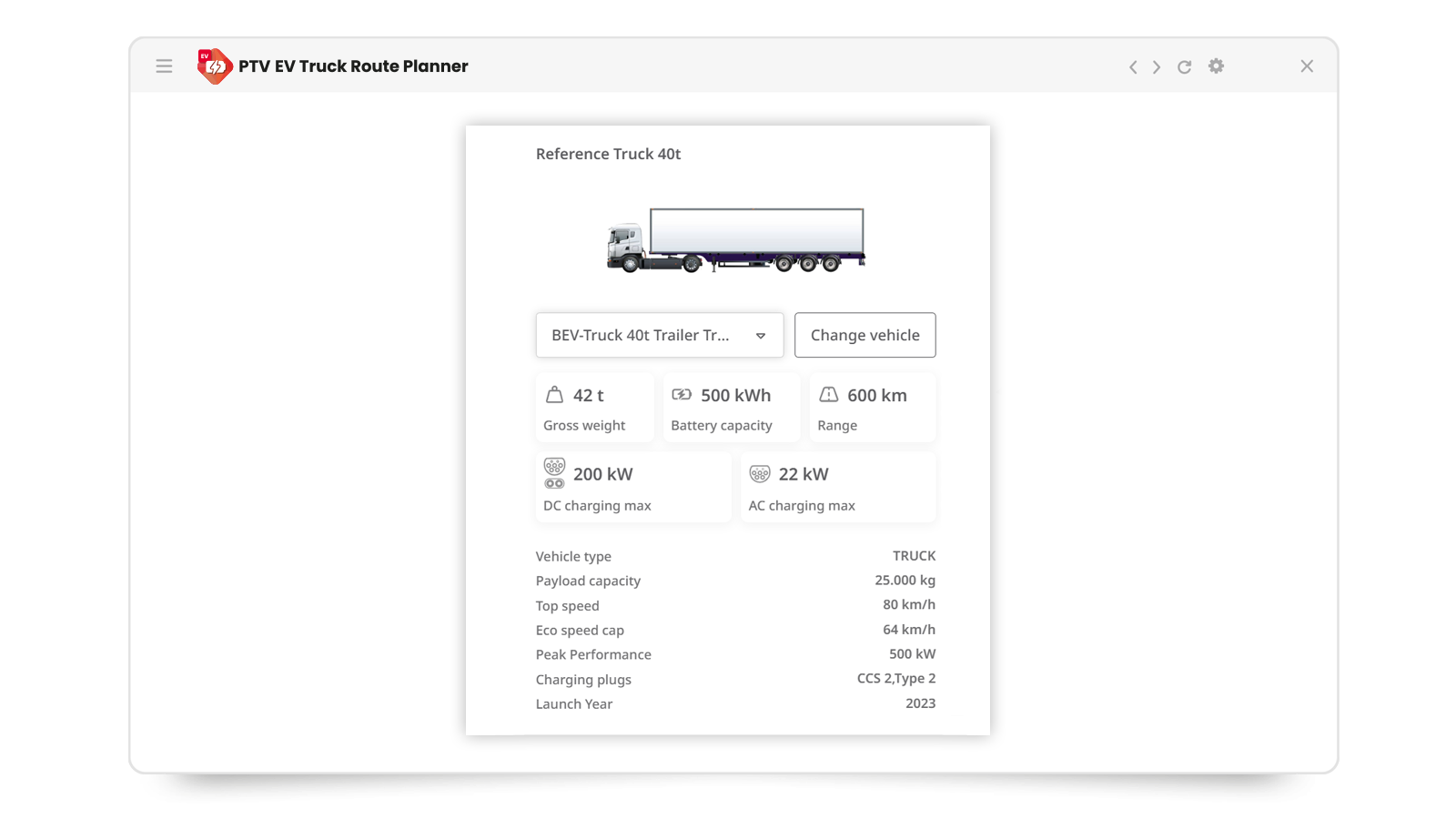

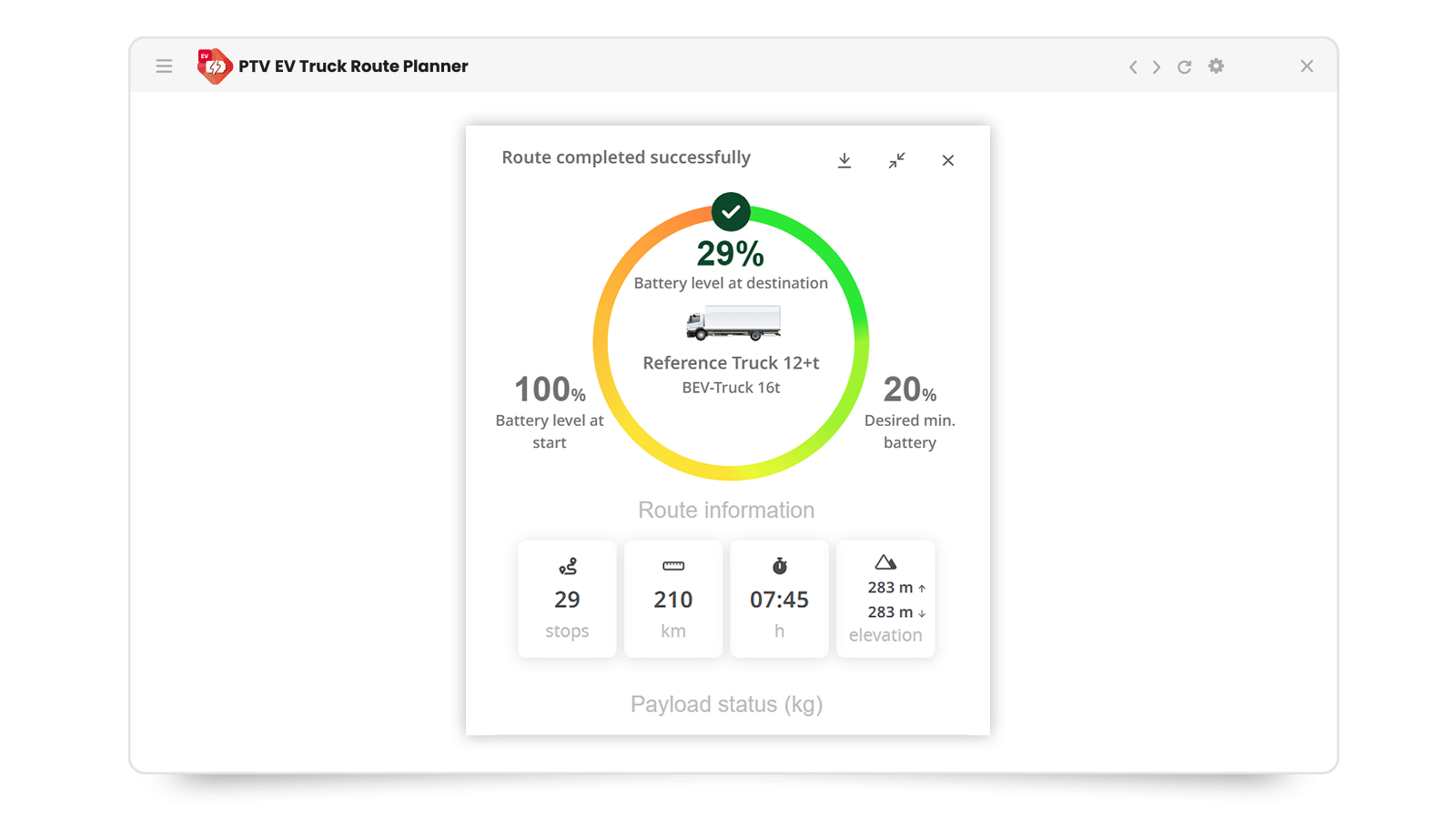

“Energy consumption calculation is the foundation for scenario planning. EV Truck Route Planner goes far beyond estimating a simple range: it enables fleet operators to simulate energy usage based on specific vehicle models. Unlike in the diesel world, EVs differ greatly from each other – for example through varying battery capacities and real-world conditions.

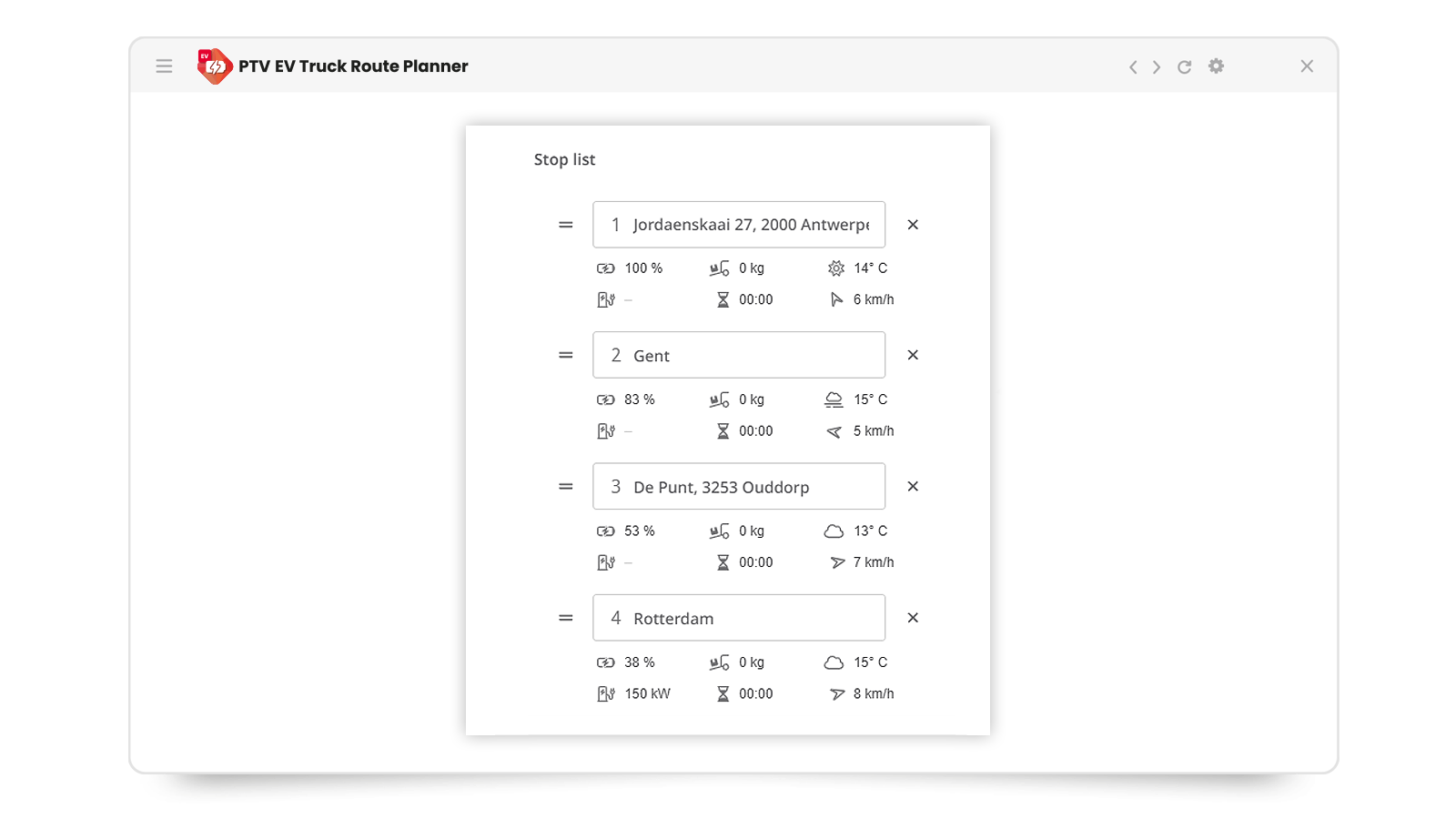

The planner incorporates charging stops, payloads, service times, as well as charging needs and timing. This creates a realistic view of vehicle deployment and operational costs. Cost impacts are calculated per factor, including given values such as tolls (often zero for EVs) or toll-km. Fleet operators can benchmark against diesel operations and plan routes that balance efficiency, emissions, and long-term operating expenditure.”

4. What role does simulation or scenario planning play in preparing for EV fleet deployment?

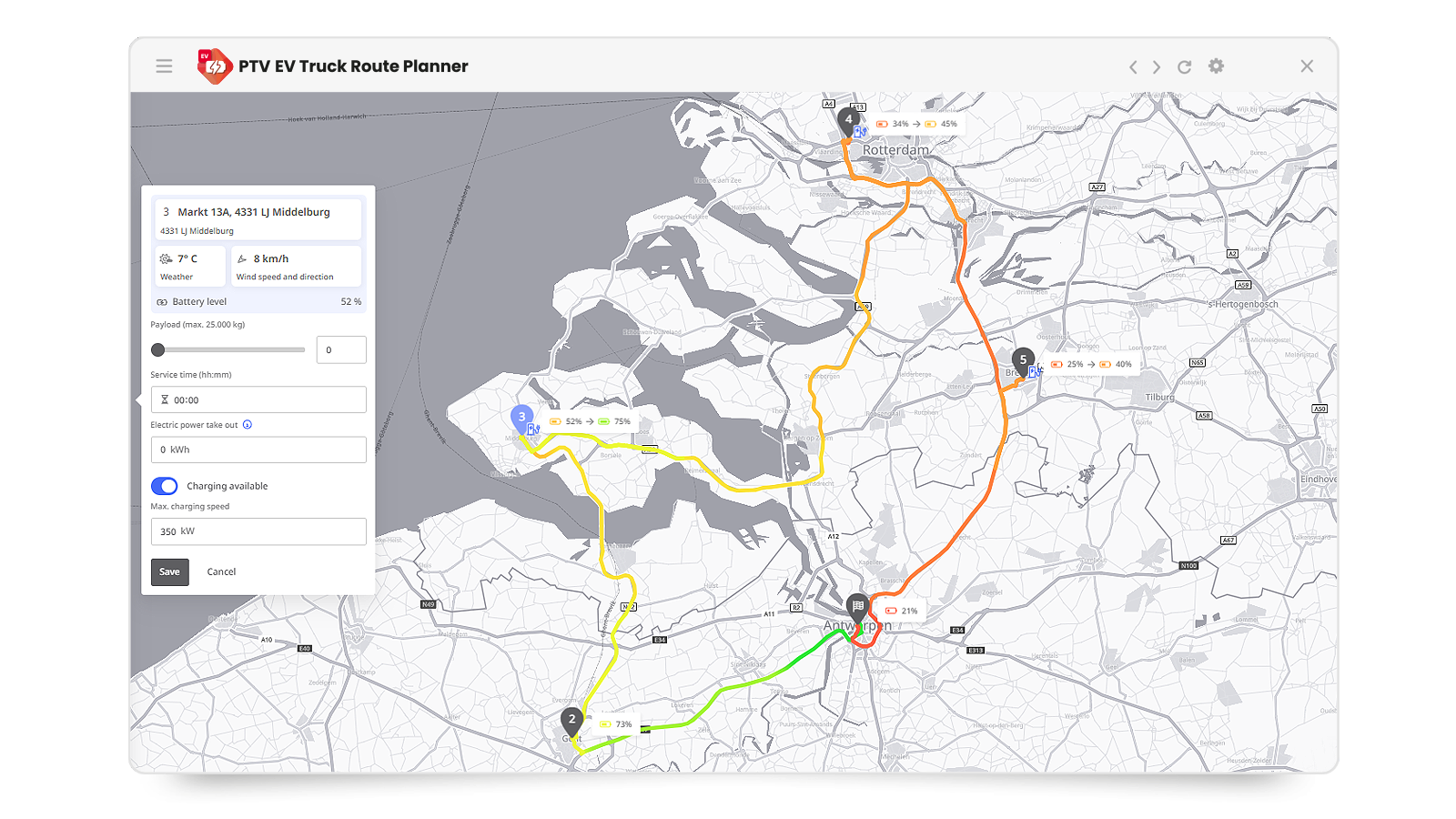

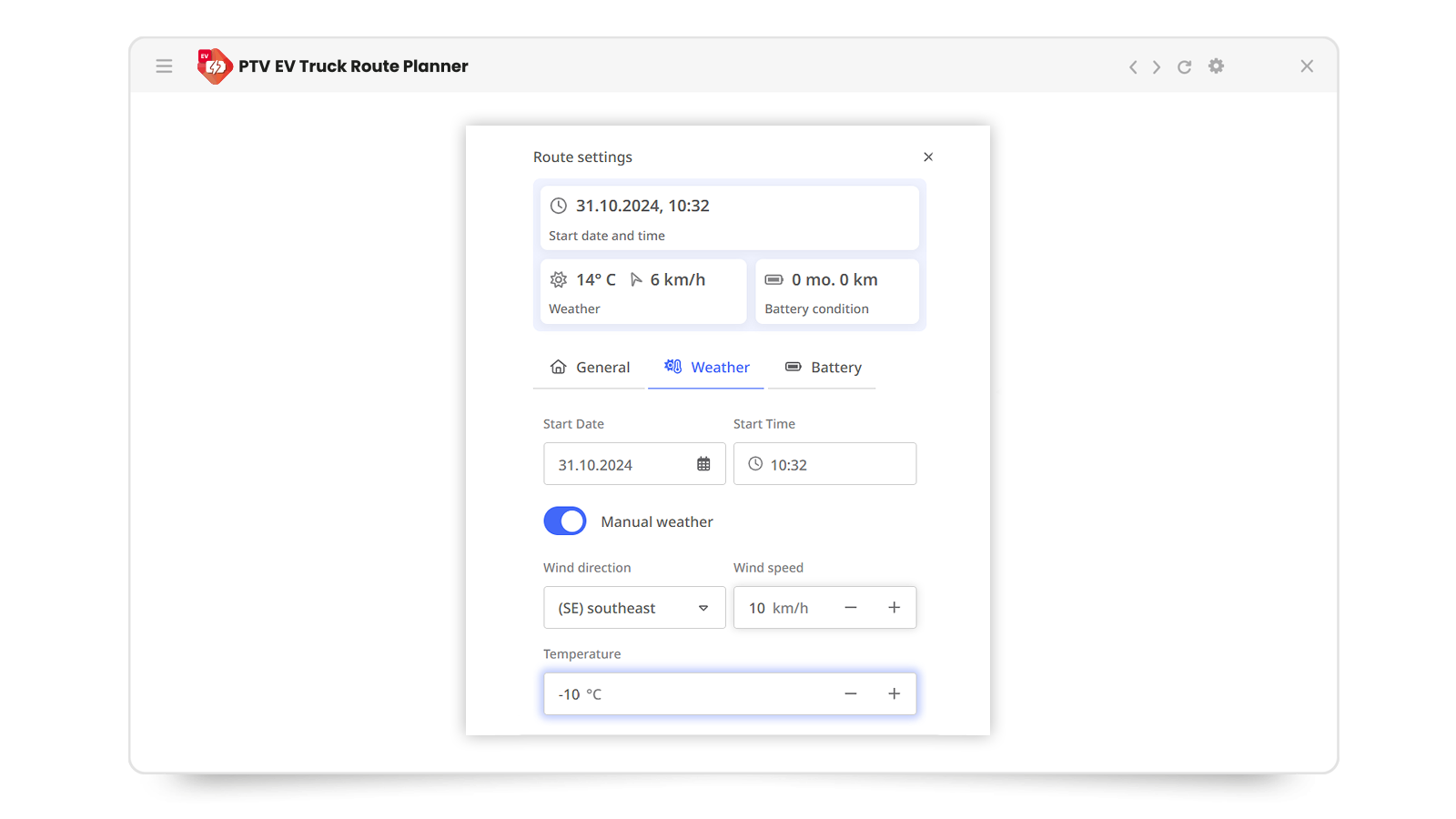

“Simulation plays a critical role in helping logistics teams make informed, data-driven decisions when transitioning to electric fleets. It allows planners to test different routing and charging strategies, compare vehicle configurations, and evaluate the impact of variables like payload, weather conditions, or battery capacity, all before making real-world changes. These scenarios help uncover where charging infrastructure is needed, what type of vehicles are best suited for specific routes, and how seasonal factors like winter temperatures might affect performance. Ultimately, simulation provides the KPIs and stability checks needed to plan confidently and avoid costly surprises.”

5. What data is needed to plan EV routes?

“First, understanding the transportation needs is essential. This begins with assessing current routes, vehicles, and their key performance indicators (KPIs). While this data isn’t required for the routing itself, it provides a valuable overview of existing operations. For actual route planning, you need specific inputs: the vehicle model to be simulated, the date of simulation, and key route details such as stops, payloads at each stop, and optionally, service times, available charging options and their speed, as well as the ePTO energy consumed at each location.”

6. What does optimized mean in an EV context and how should planners redefine success?

“In the context of electric vehicles, optimization starts with feasibility. Routes must be achievable within the vehicle’s range, with a buffer to ensure safe operation. Depots need to supply enough energy for charging, and in some cases, additional battery storage may be required to support operations.

Cost-effectiveness is another key factor. In countries where tolls are lower for electric vehicles such as Germany, Switzerland, Austria, and soon the Netherlands, planners should prioritize those routes for EVs to maximize savings. Depot charging is generally more economical than public charging, and depots can further reduce energy costs by using solar power and battery buffering.

Finally, optimization also means enablement. Some areas are only accessible with electric vehicles, and EVs offer advantages in specific regions, for example, at the Brenner Pass, where they face fewer restrictions. These factors all contribute to a broader definition of success in EV planning.”

7. Which EU regulations should logistics companies be aware of when planning electric truck routes and how does PTV EV Truck Route Planner help them stay compliant?

“Regulations are a key driver for electrification in logistics. In the EU, strict CO₂ targets for heavy-duty vehicles are pushing the industry to act now. Operators must consider frameworks like the Fit for 55 package, the AFIR mandate for charging infrastructure, and updated CO₂ emission standards, all of which influence how fleets are planned and operated. PTV EV Truck Route Planner supports companies in aligning with these requirements by helping assess route feasibility, plan infrastructure needs, and simulate long-term compliance strategies. It offers practical features that support compliance such as identifying zero emission zones (ZEZs), toll roads, and route restrictions that may affect electric vehicles. These insights help planners avoid costly missteps and ensure their operations stay aligned with evolving EU standards.”

8. If you were advising a fleet director today, what would you say is the one strategic move they must make to stay ahead in EV planning?

“The first thing I would recommend is reviewing depot grid access and exploring cost-effective ways to expand it. This is often the most limiting factor when it comes to fleet electrification.

Once that’s assessed, the next step is to develop scenarios that start with depots already equipped with sufficient energy for charging. These should take into account different vehicle variants and logistics use cases. For example, regular inter-depot routes are straightforward candidates, and planners can also identify the most EV-optimal routes from their existing operations, those with low operating costs where diesel trucks are currently expensive to run.

Starting with a first battery electric vehicle (BEV), perhaps through leasing, along with the necessary infrastructure, is a practical way to gain experience early on.

It’s also important to include charging scenarios in your planning from the beginning. As you scale, expanding those scenarios to include route optimization for mixed fleets, combining electric and diesel will be key to boosting total cost of ownership (TCO) and long-term efficiency.”

9. What’s one thing the industry keeps talking about but you think is overhyped or misunderstood?

“Well, this may be hydrogen-based concepts like fuel cell vehicles. It’s a great future concept, but currently the costs are too high, there isn’t enough green hydrogen, and there are technical difficulties. Meanwhile, electric trucks are already reaching ranges that, combined with megawatt charging, make a lot more possible. The hype around hydrogen is declining significantly at the moment, but there may be opportunities when green hydrogen reaches a price around €5/kg, especially if we don’t have sufficient electric energy at depots to charge electric trucks.

Dive deeper – The Future of EV Logistics: Next-Gen Route Planning

Fleet electrification itself is not overhyped at all. It’s the game changer that will improve TCO year by year, particularly due to advancements in battery technology, falling prices, and the growing availability of public infrastructure. These developments will increasingly enable long-haul applications.”