Today’s logistics landscape requires companies to be able to swiftly act on information and take corrective action to prevent further disruption. That’s where transport control tower software comes in. When integrated into your supply chain management systems and processes, it can help you to better plan, track, and manage your logistics flows and make more informed decisions when challenges arise. In this article, we’re going to explain exactly what a transport control tower (TCT) is, the benefits it can bring, and the factors to consider when deploying one within your organization.

Transport control tower: a definition

A transport control tower is a centralized way to collect, manage and analyze data that can then be used to make more strategic operational decisions in the future. They are typically used by shippers, carriers and logistics service providers to track, monitor, and manage transport movements across the supply chain. Whilst people and processes are important to TCTs’ success, technology plays an increasingly key role in helping to turn data into actionable insights.

What are the key functions of a transport control tower?

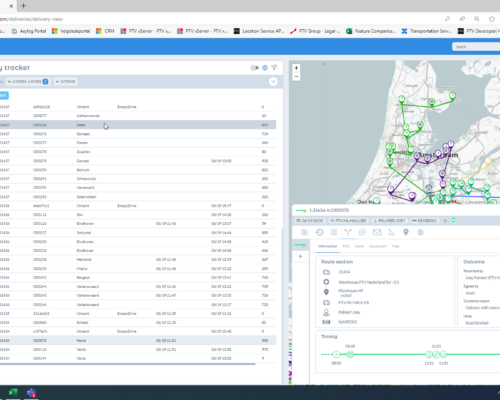

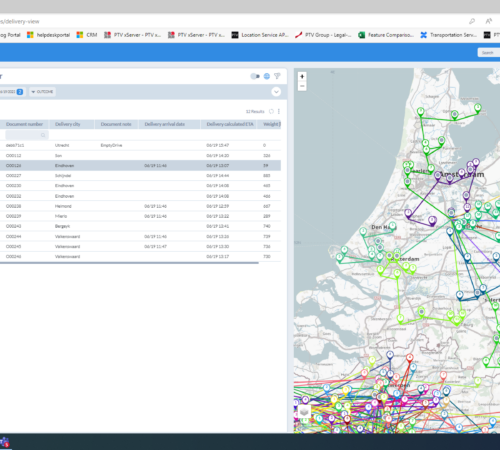

One of the main functions of a TCT is to provide better freight visibility. This is done by gathering data from different sources across the transport supply chain (including carriers, warehouses and forwarders) and incorporating external data, such as live traffic conditions. The use of GPS and internet of things (IoT) technology means information can be collected and shared instantly with stakeholders via dashboards and API connectivity in a real-time visibility platform.

TCTs also facilitate the collection and management of digital documentation, including barcode scanning and electronic proof of delivery (ePOD), through mobile driver apps. This can be accessed by all stakeholders at any time, providing a single source of truth for everyone to work from. Real-time communication and collaboration are also supported by TCTs through functions such as customisable notifications and alerts and live chats between different stakeholders. This enables everyone involved, including the customer, to stay on top of changes to scheduled deliveries.

Most TCTs will connect to warehouse management systems (WMS), enterprise resource planning (ERP), transportation managements systems (TMS) and route planning and optimisation software. The data and insights that are generated from the TCT can feed into these systems, helping to continuously improve operational efficiency.

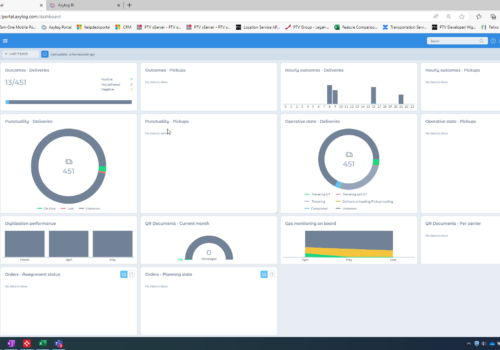

Finally, smart TCTs can also incorporate advanced analytics. This is what takes it beyond simply an operations monitoring tool to one that can add real value to a business. After analysing all the data shared via the software, advanced AI and machine learning (ML) algorithms can provide insight into any changes or disruptions, assess their impact and help create improved responses.

How to get control? It’s more than just a control tower!

This playbook clarifies how a control tower helps you regain control over your transport operation.

The benefits of a transport control tower

There are several payoffs for incorporating a TCT into your operations, including:

How to deploy a transport control tower

To successfully implement a TCT several factors need to be considered. Firstly, before any decisions are made, organisations should scope the business needs that could be met by a TCT. From here, specific use-cases can be defined, starting with those that will add most value to the business. For example, coordinating and managing a multi-carrier environment with multiple telematics providers to create a single source of truth and increase overall transparency in the planning process. By approaching it this way, organisations are more likely to see success, as the deployment can be tailored to the specific requirements of the use case and KPIs can be used to track the outcomes. After a successful roll-out with one use case, it can be scaled to others. And, with ongoing monitoring and iterating of each use case, businesses can ensure long-term continuous improvement.

Choosing the right technology is another key factor in a successful deployment. Not only should the platform offer real-time supply chain visibility, but it should also facilitate analysis that can lead to actionable insight. It’s also important to consider how it can integrate with the organisation’s existing transport management systems, or others that might help to improve different areas of operational efficiency. Some organisations look to develop this technology themselves, which requires them to build a data lake and layer business intelligence on top. Many now, however, choose to introduce transport control tower software which already includes powerful analytics capabilities and can provide a quicker way to get started.

It’s also important to make sure all stakeholders are involved in the process. End-to-end integration across different functions within the business, with the customer and with other external actors increases transparency and improves communication. For this though, everyone involved needs to have the right skills to understand the outputs given by the control tower and be empowered to take actions based on these outputs when necessary. This might involve a change in management processes.

Implementing a TCT is not as simple as buying software and letting it run. As highlighted above, there are other operational factors to consider relating to people and processes, which can create challenges. Here are some to consider:

What are the challenges to consider?

TCTs in action

Companies across the logistics supply chain are using TCTs to optimise their operations, increase efficiency and improve customer service. For example, Fineli Group – a major player in Italy’s meat production sector – have implemented a TCT using PTV Axylog. For a company that has less than 16 hours to deliver the finished product after receiving an order, real-time visibility of the delivery is essential. In the past, each shipment was monitored via phone or email, with only anomalies being recorded. Now, with a TCT in place, they have greater visibility of the logistics flow as a whole and in detail – from factory to customer – enabling them to identify and immediately act on any issues that arise during the delivery process. This has given them a greater awareness of the areas they need to improve on to deliver a higher level of service to their customers.

The Italian supermarket chain, CRAI, has also implemented a TCT that uses PTV Axylog. They implemented this in conjunction with a route optimisation tool to help them provide a better customer service without increasing transportation costs too much. With their TCT, the operations team gets a real-time overview of the availability of vehicles and potential restrictions on the delivery route. This can be used to adapt routes on the spot, or to consider in future planning. In addition, the drivers can easily use the ePOD element of PTV Axylog’s mobile app to ensure the delivery is received safely. And in case of any dispute at the point of sale – for example, a damaged package on delivery – it can be handled in real-time with the driver taking a photo of the item and sharing notes directly with central office who can act immediately. Overall, introducing a TCT has allowed CRAI to offer a higher quality service without overspending.

The future of transport control tower technology

As the benefits of TCTs are realized by businesses, and their role in supporting transport and supply chain management increases, the technology is likely to develop so that it can deliver even more value to businesses. In the future, TCTs are likely to play a central role in autonomous (or self-steering) supply chains. Here, AI and ML can be used to not only analyze situations and identify the most effective solutions but to also execute them without the need for human intervention. This will ultimately increase operational efficiency even further, resulting in improved revenues lower costs for businesses, and a better experience for customers.